Turns out it was the starter motor and a judicious tap with a hammer on the motor would spring it back to life.

Now this is obviously not a permanent fix and sooner or later it would fail permanently.

New starter motors can be £200+ & then there is the garage charges making this a costly failure.

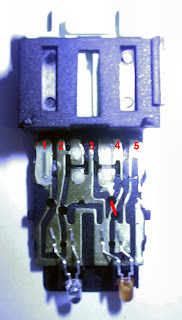

A few google searches and the most likely issue is the solenoid contacts so I purchased a kit from repairkitsuk. I paid the extra and got the kit next day.

The starter motor is a tad awkward to get at to say the least & an assistant will make life a lot easier.

To remove the motor you will need a

- 13mm socket

- 15mm socket

- 3 inch extension

- universal joint

- 3 ten inch extenders

- possibly 13 & 15mm spanners

- 1/2 inch drive

- 12 or 14mm spanner - can't remember

- 8mm socket

The starter motor is held on with two 13mm bolts & a 15mm nut, The two 13mm nuts are relatively easy to see & get at from underneath. The tricky one is the 15mm nut. This is located on the inside side of the starter at the top & there is not enough room to get a socket & ratchet in from the top.

- Disconnect the battery

- First off remove the top engine cover. Not absolutely necessary but it lets a lot more light in

- Disconnect the bottom pan & shove to the LHS.

- Disconnect the electrical connections

- Loosen the two 13mm nuts - access from underneath.

- 15mm nut

- attach the 15mm socket, 3 inch extension & universal

- get the assistant to attach this to the nut accessing the starter from above & stay there waiting...

- Connect the three 10 inch extensions to the drive

- NB access is not from fully underneath

- Insert the extension set from the front above the floor pan & differential at an angle of about 30 degrees upwards. You might see the assistants fingers.

- The assistant can then get the extension to connect in to the universal

- Undo the 15 mm nut

- Remove the two 13mm nuts

- The starter motor is now free to remove.

The instructions provided by repairkitsuk were perfect. We actually only changed the plunger & contacts. Other parts are provided but we decided everything was good.

Assembly is simply the reverse process.